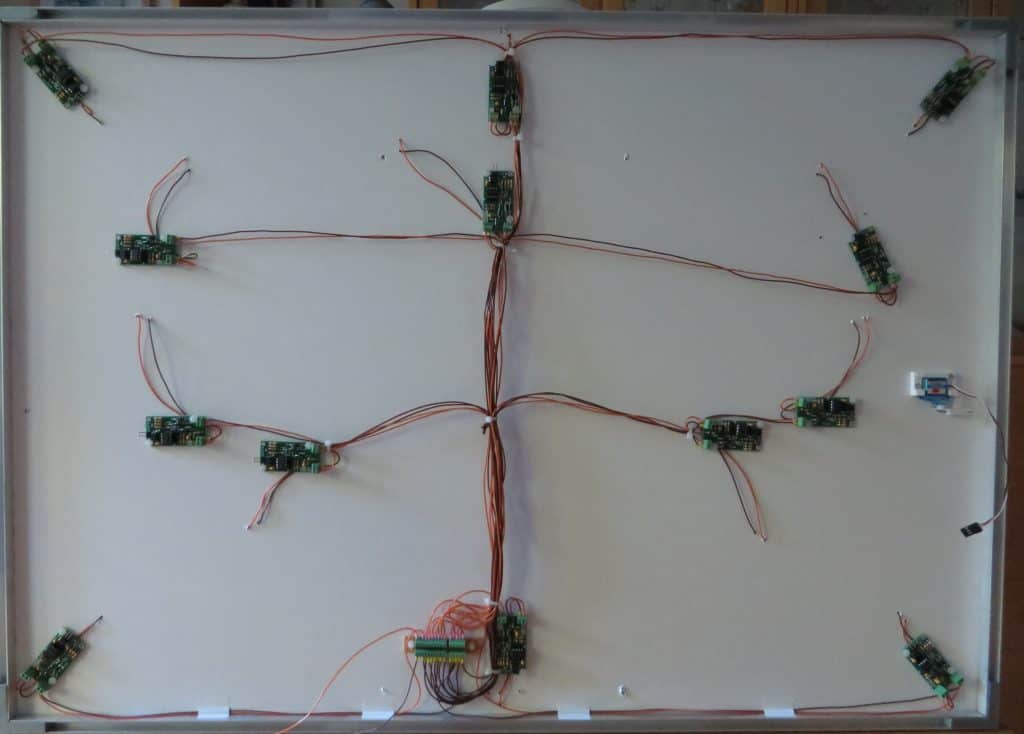

The 13 occupancy detectors for the 13 sections have been connected to a distribution point. The wires have ferrules at each end so that the screw down connectors don’t break the stranded cables.

The layout was then tested using a Dapol pacer set and all but two sections performed correctly.

Some investigation traced the problem back to the distribution point where the solder had not flowed around two of the connector pins.

The solder was quickly reflowed and every worked as it should.

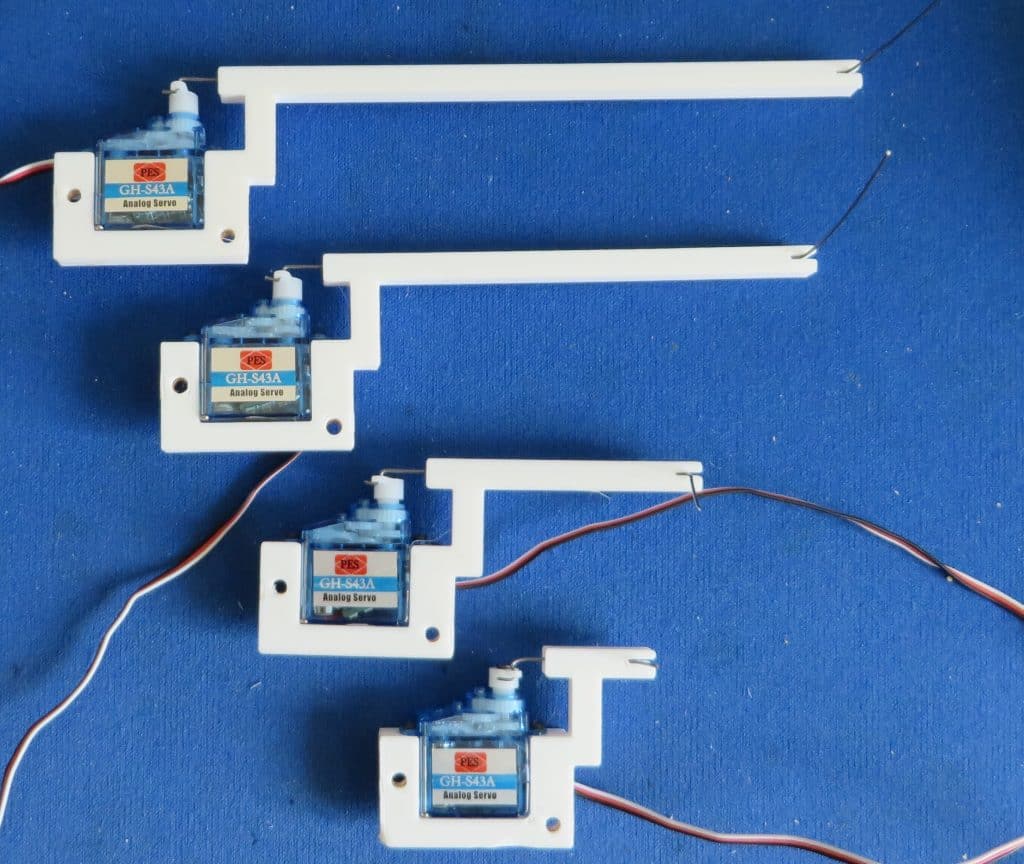

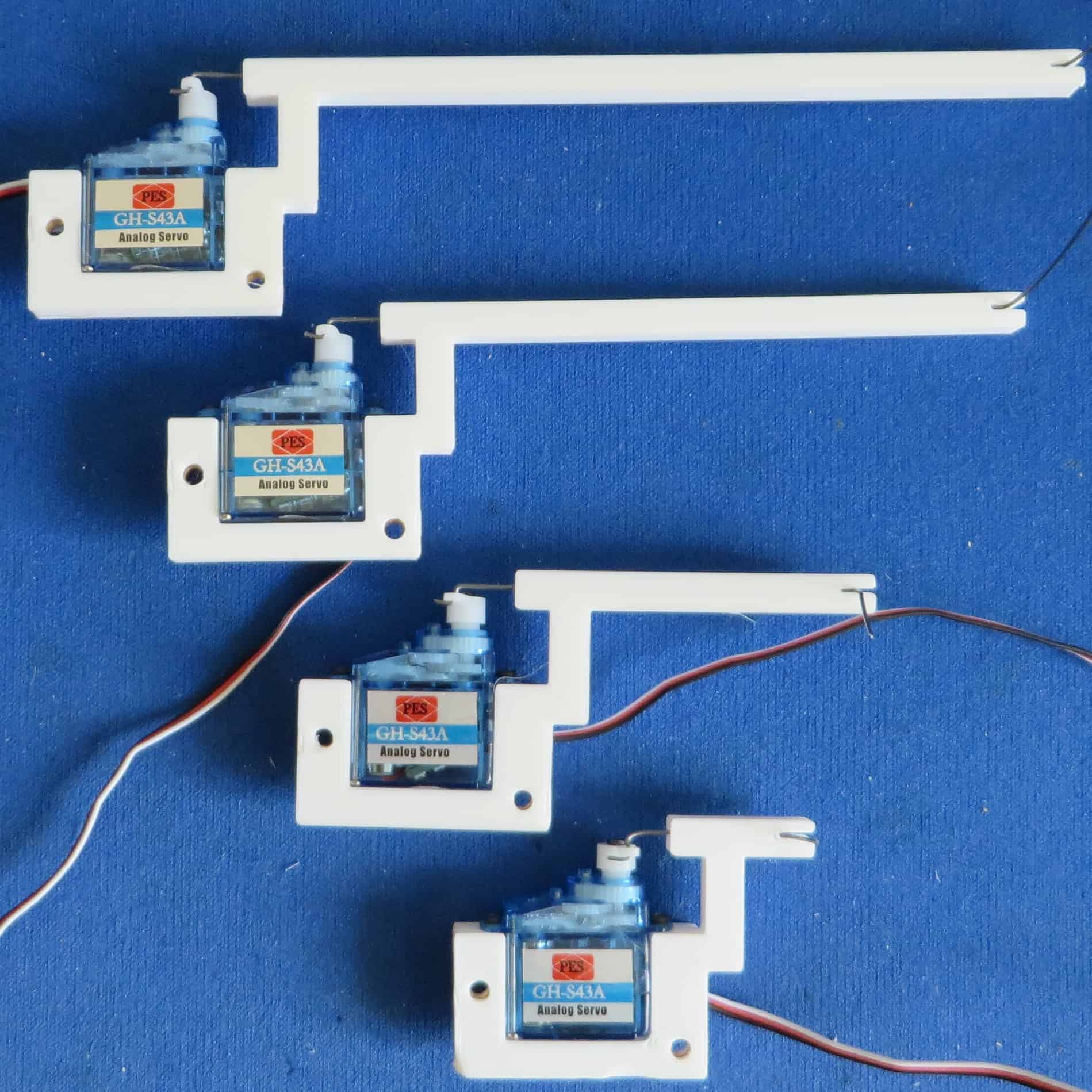

The 3D printer was used to create some servo mounts for the 3.7g servos. Four of the mounts could be installed with the short guide bar. However the second cour required the bars to be extended either to avoid some trackwork above that interfered with the fixings or to avoid some of the dropper wiring.

Some weakness in the 3D print have been detected where the servo is screwed to the mount. The fixing holes are very close to the edge and this is causing two layers to part company. The mounts will be used as they are but a new version has been produced that is completely solid – the normal printing operation has only 15% of materials inside the solid blocks.

Spares will kept on hand so that any failures can quickly be rectified.